Research Areas

Drop-in Technologies for Membrane Enhancement

Industrial separations consume between 10 – 15% of total U.S. energy consumption, in part because of thermal distillation. One strategy for reducing the energy impact of this highly inefficient process involves switching to membrane-based separations, which will require the creation of membrane materials that can endure high temperature, caustic, and organic environments. Rather than engineer new membrane chemistries that are difficult to bring to market, we are upgrading existing membranes using drop-in technologies to improve their stability % performance, allowing them to be used in this space.

One potential way of surpassing the permeability/selectivity tradeoff found in traditional polymer membranes for gas separations is by making mixed matrix membranes (MMMs). These are composed of a continuous polymer phase with dispersed crystallites (metal organic frameworks, or MOFs) that can improve the separation properties of the membrane relative to the base polymer. MMMs have shown promising results in separating mixed gas streams, but their conventional synthesis involves solution-based methods that are difficult to bring to industrial scale. In the Bergsman group, we propose that MMMs can be made through vapor phase methods. Using vapor phase infiltration (VPI) we seek to dose reactants sequentially into a polymer matrix to grow MOFs in situ within the pores of the polymer. We hope that this novel synthesis method will allow us to make membranes that are highly permeable, selective to specific gases, and easily scalable.

Another project in this area is centered on nanopore technology. The objective is to develop thin film chemistries for the surface functionalization of solid state nanopores in order to optimize their use in protein sensing as well as to provide a scaffolding support for the integration of biological nanopore sensors on the solid state surface. This is performed with molecular layer deposition (MLD), a vapor phase deposition technique that is critical to the surface functionalization of nanopores due to its ability to penetrate nanometer scale spaces and its ability to create angstrom-level accuracies of thickness. These synthetic and hybrid synthetic-biological nanopores have applications in biomedical protein sensing as well as potentially in desalination or other separations applications.

Nanostructured Catalysts for Energy Conversion

To achieve decarbonization using intermittent carbon-free energy resources like solar and wind, technologies for storing that energy and converting into portable fuels will be essential. One strategy for efficiently converting this energy into fuels is electrocatalysis, where electrical current is applied to catalyst surfaces to split water into hydrogen and carbon dioxide into hydrocarbons. To make these catalysts efficient enough for a global energy, we must improve upon the current start-of-the-art by introducing stable nanostructures with precise features and atomic compositional control. Projects include:

Leveraging enzyme-like confinement to improve activity & selectivity

Stable coatings that protect the catalyst surface from parasitic reactions with the electrolyte

High Throughput Materials Screening

The future of materials design will rely on the ability to quickly screen materials of a variety of compositions and properties for their performance. To enable this screening, we are building systems that can simultaneously create a wide range of materials compositions, allowing us to quickly optimize for a particular application.

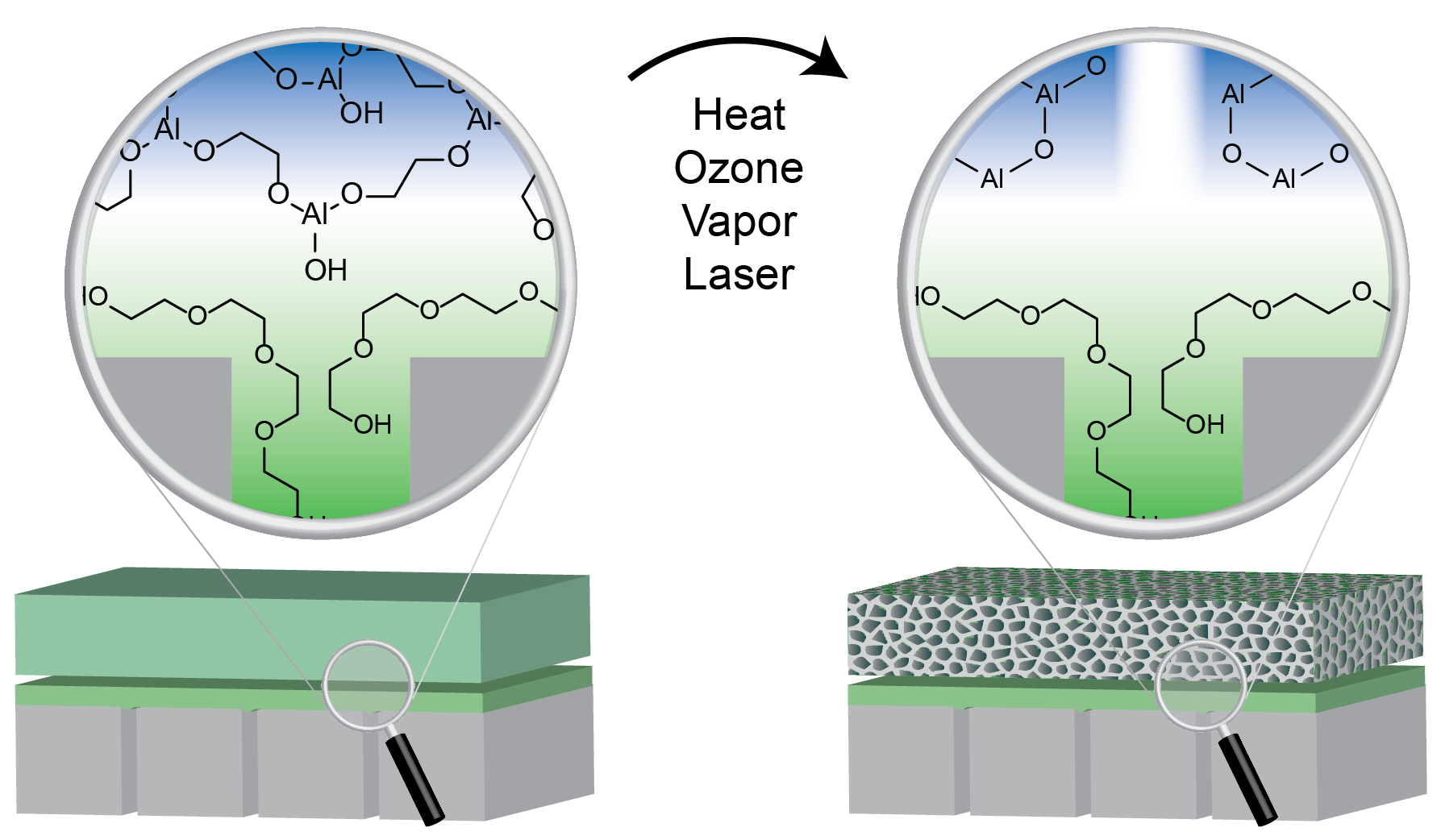

One project in this area explores new chemistries for vapor phase infiltration (VPI) to upgrade polymeric membranes, altering their properties and ultimately expand the application of membrane separations. Commercially available polymeric membranes are unstable in many industrial processes due to a low resistance to organic chemicals and high temperatures, limiting their applicability. Using VPI processes, inorganic nanoparticles could be introduced into polymers, forming a secondary network. The VPI-treated polymeric membranes showed an increase in thermal and chemical stability with inorganic nanoparticles which inhibit solvation and melting, but also decrease in flexibility. The goal of the project is to find new VPI chemistries with which produce chemically stable, thermally resistant, and flexible polymeric membranes after VPI treatment. Using the high-throughput reactor, it allows a faster screening of new chemistries with various process conditions.

Rethinking Membrane Design

Currently, membrane structures and properties are the result of the synthesis method used to make them. To break the barrier of permeability/selectivity, we are recreating old membrane chemistries using new synthesis techniques, allowing us to decouple the synthesis/property relationships. These tools are also being used to make previously unsynthesizable membrane architectures, such as low cost ceramics.

In order to address the issue of global water scarcity, we are looking towards membrane separations as an energy efficient method of water treatment. Currently, these membranes are made by interfacial polymerization. Since this method uses and relies on solvents, it limits the exploration of different membrane chemistries and designs. This project uses molecular layer deposition (MLD) which eliminates the use of solvents, allowing us to explore a wide variety of membrane designs that may not be possible with interfacial polymerization. MLD will allow us to even expand beyond polymer membranes to try other materials such as ceramic and hybrid organic-inorganic materials. Trying a variety of membrane designs will allow us to analyze trends between membrane chemistry and morphology and their performance in water treatment.

Hydrogels are 3D networks of crosslinked hydrophilic polymers with a vast array of applications across biology, medicine, engineering, food science, and more. Many types of hydrogels, due to their biocompatibility and transport properties, are ideal for uses such as cell encapsulation, drug delivery, and membrane-based separations. Meanwhile, industrial microbiology is a rapidly advancing field that offers energy-efficient alternatives to traditional chemical manufacturing methods by engineering microbes to produce high-value products from simple raw materials, like glucose. This project aims to harness the advantages of hydrogel membranes to design modular bio-based processing units. Within these processing units, the highly selective hydrogel membrane serves to both provide an extracellular matrix for the engineered cells, and perform real-time product separations, thereby circumventing the need for energy-intensive thermal separations.